BT-HMC gidrawlik saklaýjy

Önümiň parametri

| Pişik | Ölçegi | ||||||||

| D1 | D2 | D3 | L | L1 | L2max | L2min | M | ||

| HSK40E | HMC06-70L | 6 | 30 | 42 | 70 | 25.5 | 26 | 38 | M5 |

| HMC08-70L | 8 | 32 | 26 | 28 | M6 | ||||

| HMC10-75L | 10 | 34 | 75 | 32.6 | 34 | 45 | M8 | ||

| HMC12-80L | 12 | 36 | 80 | 40 | 36 | 50 | |||

| HSK50E | HMC06-70L | 6 | 30 | 70 | 25.5 | 26 | 38 | M5 | |

| HMC08-70L | 8 | 32 | 26 | 28 | M6 | ||||

| HMC10-80L | 10 | 34 | 80 | 32.6 | 34 | 45 | M8 | ||

| HMC12-85L | 12 | 36 | 85 | 40 | 36 | 50 | |||

| HMC16-90L | 16 | 40 | 90 | 43 | 41 | 52 | |||

| HMC20-90L | 20 | 42 | 64 | ||||||

| HSK50A | HMC06-70L | 6 | 30 | 70 | 25.5 | 26 | 38 | M5 | |

| HMC08-70L | 8 | 32 | 26 | 28 | M6 | ||||

| HMC10-80L | 10 | 34 | 80 | 32.6 | 34 | 45 | M8 | ||

| HMC12-85L | 12 | 36 | 85 | 40 | 36 | 50 | |||

| HMC16-90L | 16 | 40 | 90 | 43 | 41 | 52 | |||

| HMC20-90L | 20 | 42 | 64 | ||||||

| HSK63A | HMC06-80L | 6 | 32 | 48 | 80 | 32 | 29 | 46 | M5 |

| HMC06-125L | 125 | 38.5 | 28 | 44.5 | |||||

| HMC06-150L | 150 | ||||||||

| HMC08-80L | 8 | 34 | 80 | 32 | 29 | 46 | M6 | ||

| HMC08-125L | 32 | 125 | 38.5 | 28 | 44.5 | ||||

| HMC08-150L | 5 | 34 | 150 | ||||||

| HMC10-80L | 10 | 36 | 50 | 80 | 32 | 37 | 50 | M8 | |

| HMC10-125L | 125 | 40 | 51 | ||||||

| HMC10-150L | 150 | ||||||||

| HMC12-80L | 12 | 38 | 80 | 32 | 32 | 50 | |||

| HMC12-125L | 125 | 41 | 37 | 51 | |||||

| HMC12-150L | 150 | ||||||||

| HMC14-80L | 14 | 39 | 80 | 32 | 40 | ||||

| HMC14-125L | 125 | 42 | |||||||

| HMC16-90L | 16 | 41 | 90 | 42.5 | |||||

| HMC16-125L | 42 | 125 | 43 | 52 | |||||

| HMC16-150L | 41 | 150 | 42.5 | 51 | |||||

| HMC18-90L | 18 | 42 | 90 | 41 | |||||

| HMC18-125L | 125 | ||||||||

| HMC20-90L | 20 | 90 | 52 | ||||||

| HMC20-120L | 44 | 120 | 52.5 | ||||||

| HMC20-150L | 42 | 150 | 52 | ||||||

| HSK100A | HMC06-90L | 6 | 30 | 48 | 90 | 31 | 28 | 44.5 | M5 |

| HMC08-90L | 8 | 32 | M6 | ||||||

| HMC10-105L | 10 | 36 | 50 | 105 | 38 | 37 | 51 | M8 | |

| HMC12-105L | 12 | 38 | 52 | 40 | |||||

| HMC14-105L | 14 | 39 | 41 | 41 | |||||

| HMC16-105L | 16 | 41 | 54 | 42 | 52 | M12 | |||

| HMC18-105L | 18 | 42 | 50 | 41 | |||||

| HMC20-105L | 20 | 43 | 54 | ||||||

| HMC25-110L | 25 | 52 | 62 | 110 | 55 | 49 | 65 | ||

| HMC32-110L | 32 | 63 | 72 | 57 | 52 | ||||

| Pişik | Ölçegi | ||||||||

| D1 | D2 | D3 | L | L1 | L2max | L2min | M | ||

| BT / BBT30 | HMC03-60L | 3 | 21 | 45 | 60 | 29 | 23 | 84 | M5 |

| HMC04-60L | 4 | ||||||||

| HMC06-75L | 6 | 30 | 46 | 75 | 24 | 28 | 50 | ||

| HMC08-75L | 8 | 32 | M6 | ||||||

| HMC10-75L | 10 | 34 | 34 | M8 | |||||

| HMC12-75L | 12 | 36 | 36 | ||||||

| HMC14-90L | 14 | 38 | 90 | 25 | 41 | 52 | |||

| HMC16-90L | 16 | 40 | 40 | ||||||

| HMC18-90L | 18 | 42 | 33 | ||||||

| HMC20-90L | 20 | 46 | 41 | ||||||

| BT / BBT40 | HMC04-90L | 4 | 28 | 8 | 24 | 42 | M5 | ||

| HMC06-90L | 6 | 30 | 38 | 28 | 44 | ||||

| HMC08-90L | 8 | 32 | 48 | M6 | |||||

| HMC10-90L | 10 | 36 | 52 | 40 | 37 | 51 | M8 | ||

| HMC12-90L | 12 | 38 | 54 | ||||||

| HMC14-90L | 14 | 40 | 56 | 41 | 52 | M12 | |||

| HMC16-90L | 16 | 42 | 58 | ||||||

| HMC18-90L | 18 | 43 | 59 | ||||||

| HMC20-90L | 20 | 46 | 60 | 53 | |||||

| HMC25-105L | 25 | 52 | 62 | 105 | 55 | 49 | 65 | ||

| BT / BBT50 | HMC06-105L | 6 | 30 | 46 | 38 | 28 | 44 | M5 | |

| HMC10-105L | 10 | 36 | 52 | 40 | 37 | 51 | M8 | ||

| HMC12-105L | 12 | 38 | 54 | ||||||

| HMC14-105L | 14 | 40 | 56 | 41 | 52 | M12 | |||

| HMC16-105L | 16 | 42 | 58 | ||||||

| HMC18-105L | 18 | 43 | 59 | ||||||

| HMC20-120L | 20 | 46 | 60 | 120 | 53 | ||||

| HMC25-120L | 25 | 52 | 62 | 55 | 49 | 65 | |||

| HMC32-120L | 32 | 63 | 72 | 56 | 52 | ||||

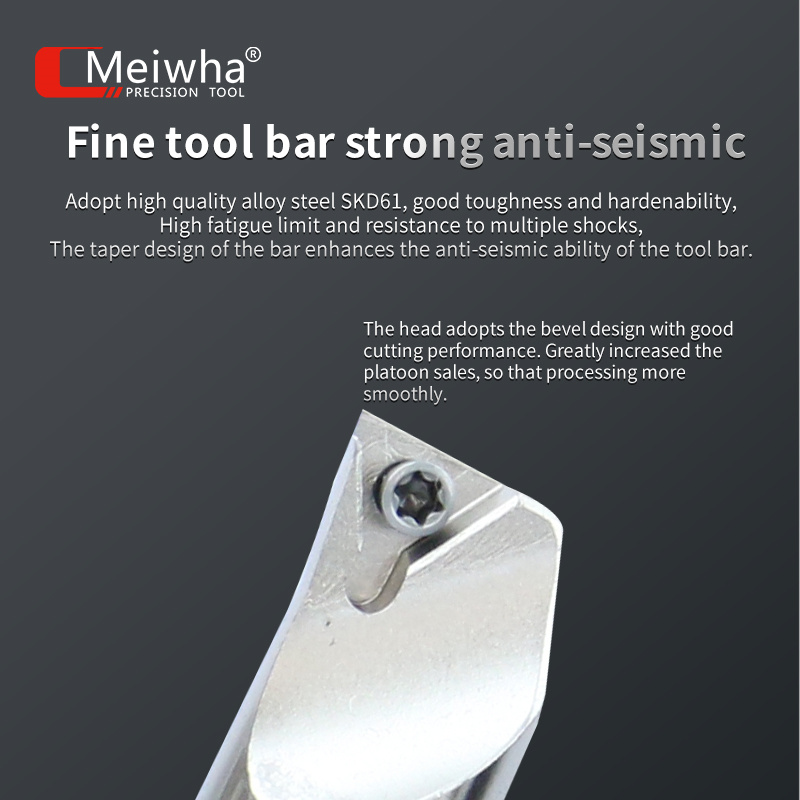

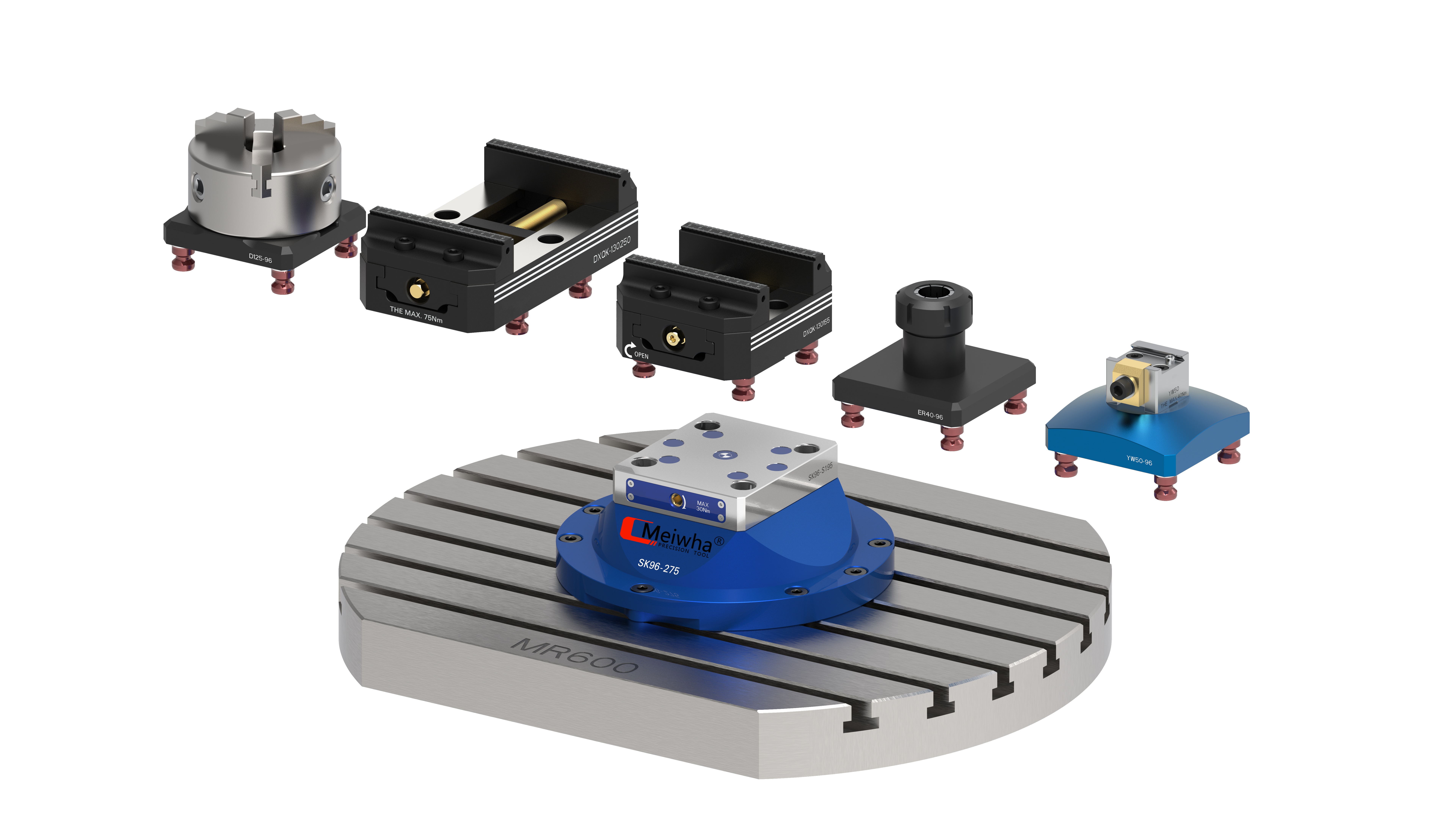

Meiwha gidrawlik guralynyň eýesi

Conokary konsentrasiýa / Uly gysyş güýji

Çäreler:

1. Gurallary salýan begleri gulplamaň.

2. H6-da çydamlylyk bilen gurallary ulanyň. D4 diametri az bolan kiçijik deşikler üçin H5 çydamlylygy bolan gural ulanyň.

3. gysyş güýjüni güýçlendirmek üçin guralyň içki deşigini we daşyny gowy arassalamaly.

4.Plaese tekiz ýa-da dogralan tutawaçly gurallary ulanmaň.

5.Kesiji guraly gysanyňyzda, gulpy berkidiň.

6. Guralyň salmagyň uzynlygy minim-mu guralyň gysyş uzynlygyndan az bolmaly däldir.

Gidrawlik berkidiji güýçli gysyş güýji

Highokary gysyjy güýç bilen ykjam umumy gurluş, guralyň hyzmat möhletini uzaldyp biljek ýokary umumy takyklyk.

Gowy tozan - subut

Guraly gysandan soň hiç hili boşluk ýok, kesýän sowadyjy we tozan aňsatlyk bilen girip bilmeýär.

Içki buraw üweýji.

has takyk işlemek üçin has çydamly, tikişli.